The management and control characteristics of UIC PCBA factory

- Addtime: 2025-10-24 / View: 74

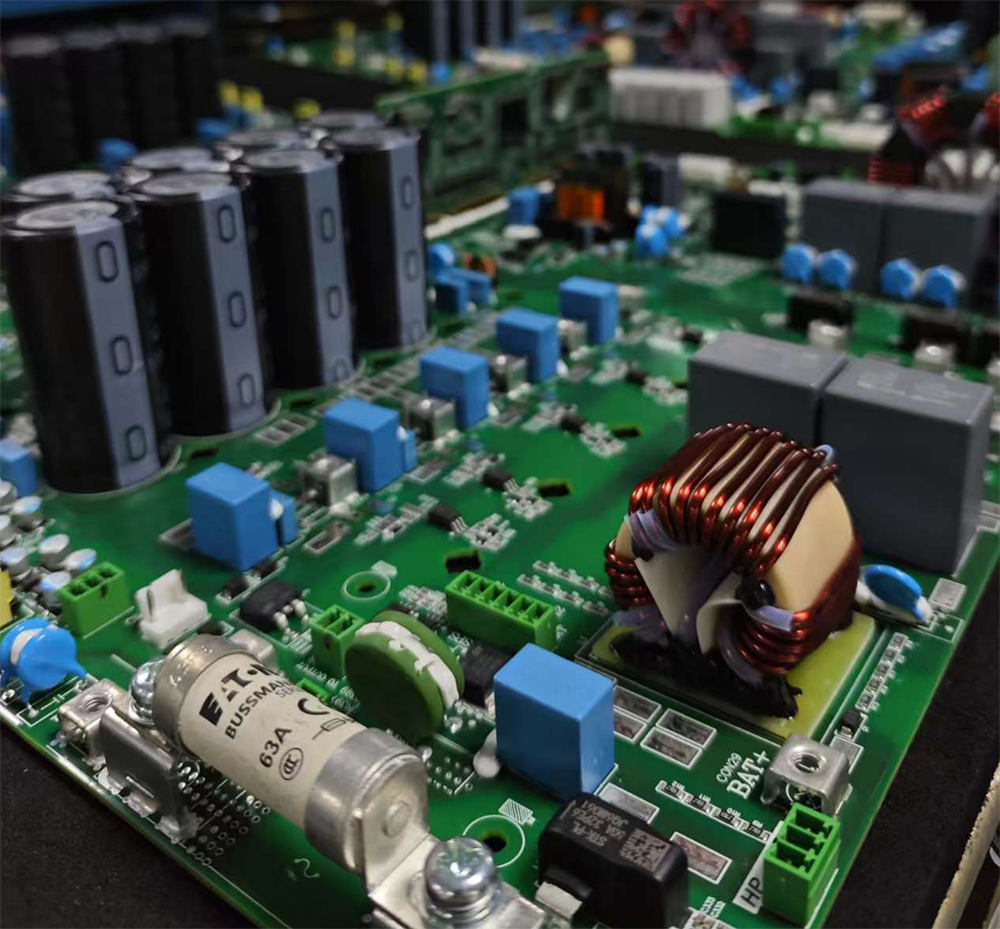

In the highly competitive electronics manufacturing landscape, a PCBA (Printed Circuit Board Assembly) factory's success hinges on a clearly defined competitive edge and a robust system of operational control. These factors are critical for attracting and retaining clients in industries such as automotive, medical, aerospace, and consumer electronics. Below are the key control characteristics that distinguish a top-tier PCBA manufacturer.

- Engineering and Process Control

Standardized Processes: Implementation of Standard Operating Procedures (SOPs) for every critical process, from stencil printing and component placement to soldering and cleaning.

Process Parameter Monitoring: Continuous monitoring and control of critical process parameters (e.g., reflow oven temperature profiles, solder paste viscosity) using Statistical Process Control (SPC) to maintain process stability.

Change Management: A formal Engineering Change Order (ECO) process to ensure all modifications are properly reviewed, documented, and implemented without disrupting production.

- Production and Floor Management

ESD and Moisture-Sensitive Device (MSD) Control: Strictly controlled ESD-protected areas and proper handling procedures for MSDs to prevent damage to sensitive components.

Traceability: Full lot-to-component level traceability through barcode/RFID systems. This is crucial for root cause analysis and product recalls, especially in regulated industries.

Lean Manufacturing Principles: Adoption of 5S, visual management, and waste-reduction techniques to create an organized, efficient, and safe production environment.

- Quality Assurance and Supply Chain Control

Incoming Quality Control (IQC): Rigorous inspection and testing of all incoming materials and components to prevent defects from entering the production line.

In-Process Quality Control (IPQC): Real-time quality checks at various stages of assembly (e.g., after SMT, after wave soldering) to identify and correct issues immediately.

Outgoing Quality Control (OQC): A final, comprehensive audit and testing process before products are shipped to the customer.

- Data-Driven Continuous Improvement

Centralized Data Collection: Utilizing MES (Manufacturing Execution System) to collect real-time data on production, quality, and equipment performance.

Root Cause Analysis: Employing methodologies like 8D or 5 Whys to systematically investigate failures and implement effective corrective and preventive actions (CAPA).

Continuous Improvement Culture: Fostering a company-wide culture where every employee is empowered to identify and suggest improvements for processes and quality.

A leading PCBA factory is not merely a facility that populates boards with components. It is a highly integrated, technologically advanced, and meticulously controlled ecosystem. Its competitive advantage is derived from a synergistic combination of advanced technology, unwavering quality standards, supply chain resilience, and operational excellence. The rigorous control characteristics across engineering, production, and quality assurance ensure that this competitive edge is consistently delivered, building long-term trust and partnership with clients worldwide.