Copper Thickness in PCB Performance

- Addtime: 2025-06-11 / View: 164

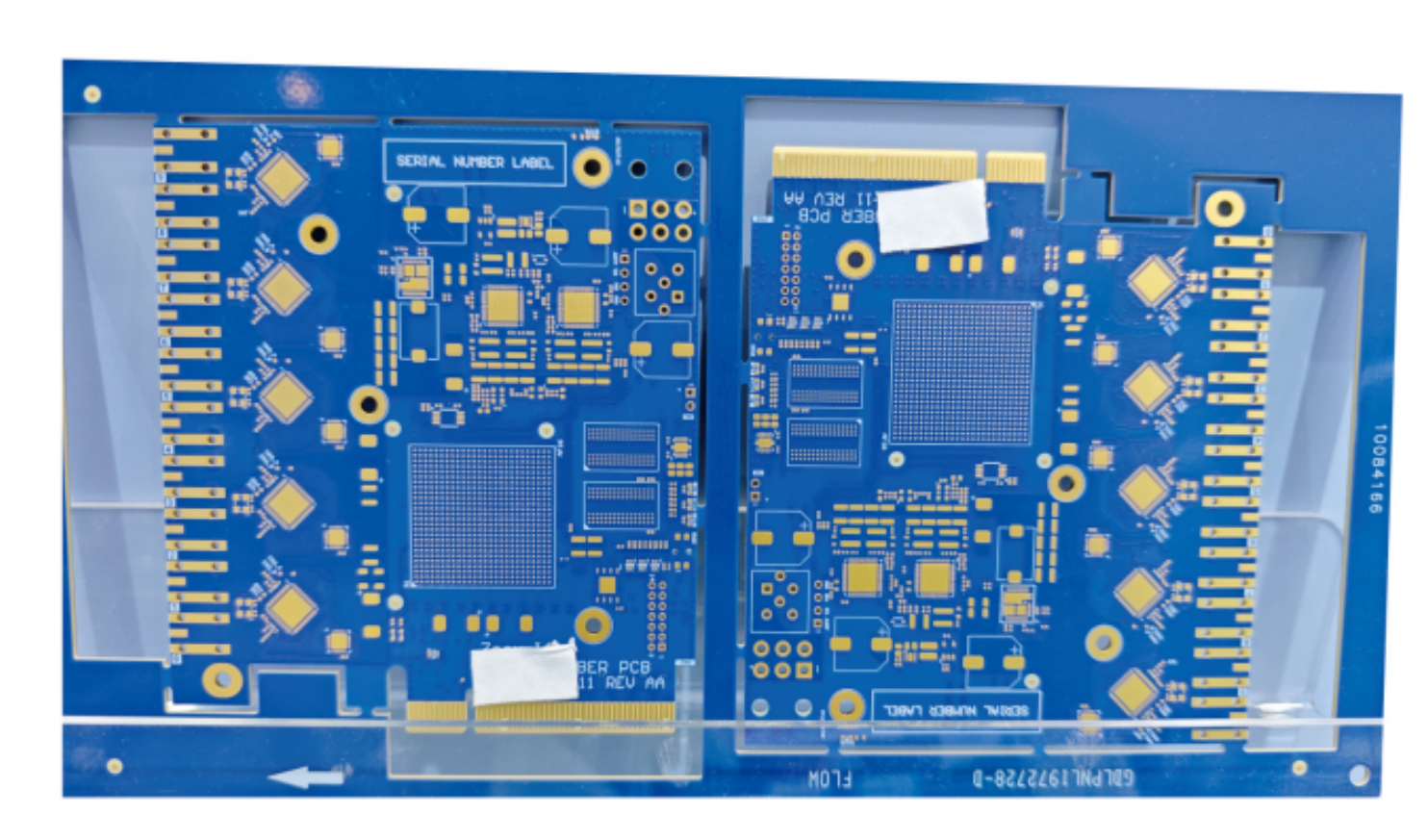

In PCB (Printed Circuit Board) manufacturing, copper thickness refers to the thickness of the copper layer, which is usually measured in ounces (oz). 1oz means the thickness achieved when 1oz of copper is evenly spread over an area of 1 square foot (ft²). The thickness of 1oz of copper is approximately 35 μ m or 1.35mil.

Copper thickness directly impacts current flow, heat management, and durability.It’s critical for high-performance PCBs.

Why it Matters:

Power Efficiency -Reduces resistance for stable current delivery.

Heat Dissipation -Can better conduct heat, thereby enhancing the heat dissipation performance of the product. At the same time, it reduces the thermal expansion of the PCB caused by temperature changes and extend service life.

Reliability-Strengthens the board for demanding applications.

Choosing the Right Thickness:

Standard options range from ½ oz to 3 oz per square foot, but selection depends on current load, thermal needs, and application.

At UIC, precision PCB design is our priority. How do you approach copper thickness in your initial design? Welcome to communicate with us.

UIC is a professional manufacturer of EMS service for global customers, providing one-stop service from product design,PCB fabrication, raw&auxiliary materials procurement,PCBA manufacturing and finished product assembly.